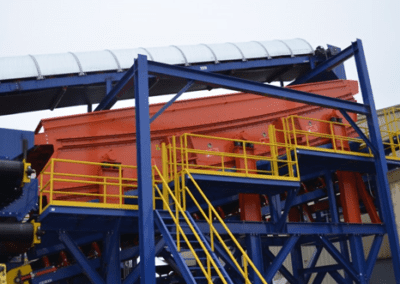

The BIVITEC® Screen

Effective Fine Screening For the Most Difficult Materials

BIVITEC® allows the screening of the most difficult materials without plugging or blinding. The unique action of the deck provides high acceleration forces on the material to keep the deck free and clear.

BENEFITS OF THE BIVITEC®

THE BIVITEC® SOLUTION

Developed to screen the most problematic materials, the BIVITEC® vibratory screener uses a unique dual-vibratory screening process to eliminate clogging and blinding of the screen mesh to save downtime and increase productivity.

To ensure the most effective screening, high-acceleration forces are transferred to the feed material. The BIVITEC® Screen achieves these high forces by dynamically tensioning and relaxing the flexible polyurethane screen mats using a dual vibration principle. Enhanced by resonance, one drive can produce two vibration movements. The screen box is accelerated approximately 2g’s while the screen mats can receive up to 50g’s.

Applications once judged impossible, can now be accomplished. Request a quote on a BIVITEC® screen for sale.

![testa[1]](https://aeiscreens.com/wp-content/uploads/2022/08/testa1.gif)

BIVITEC® Videos

Scroll through the below videos to see our vibratory screener easily handle the most difficult materials.

BIVITEC® Options

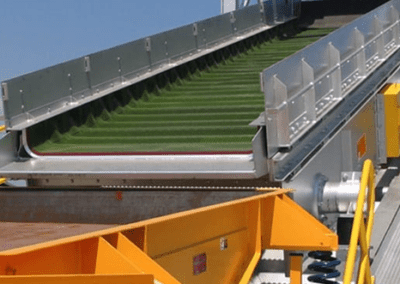

Inclined Vibrating Screen Sizes

- The BIVITEC ® is available in size ranges from 800mm x 3m (3’x10’) to 3000mm x 12m (10’x40’)

- 1,2,3 and 4 deck vibrating screens are available

- Half Deck configuration allows multiple cuts in a single deck.

Deck Options

- BIVITEC® mesh sizes range from 100 mesh to 4”

- Wire cloth, urethane, finger, 3D and other conventional scalping decks can be combined with the BIVITEC® system

- Banana design: Curved deck with steeper angle on feed end and lesser angle on discharge, provides increased capacity and efficiency

- LL Design for bulky materials: Double the panel width and double the stroke.

Vibratory Screen Options

- BIVITEC® is available in both mobile and static configurations

- Each screen is built to fit the customer’s unique specifications

BIVITEC® Testing and Sizing

To properly size the BIVITEC ® vibrating screen machine for each individual application, the following factors must be considered: material type, moisture content, feed gradation, product specifications and capacity

AEI conducts all testing on customer site to ensure real world material and operating conditions. Contact us for a test at your location.

Advantages

FINE SCREENING OF

MOIST MATERIAL

ELIMINATES BLINDING

AND PLUGGING

HIGH CAPACITY – LARGE

EFFECTIVE SCREENING

AREA

LONG LIFE

POLYURETHANE SCREEN

MATS

RUGGED

CONSTRUCTION, LOW

MAINTENANCE

HIGHLY FLEXIBLE FOR

VARYING MATERIAL

CONDITIONS

LOW ENERGY

USAGE

BIVITEC®

Proves to be the best solution for screening:

- Manufactured sands, chips, ag lime

- High-moisture materials combined with silt, mud and clay

- Incinerator ash, trash, waste coal, clay, sand and slag

- Compost, leafy materials, wood waste and peat moss

- Auto Shredder fluff, shredded tires, roofing shingles, C+D waste, RDF