MSW SCREENING

What Is Municipal Solid Waste?

Municipal Solid Waste (MSW) consists of everyday items or other refuse that have been disposed of for processing by a waste facility. A few common examples of MSW include:

- Product packaging

- Furniture

- Plastic or glass bottles

- Food waste

- Paper waste

- Old or broken electronics

MSW is generated in homes, businesses, and public facilities, like schools. In many countries, municipal waste is left outside for trash haulers to collect and deliver to a material recovery facility (MRF).

Some municipalities require consumers to sort recyclable waste before placing it out for collection. Other municipalities use a single-stream approach which doesn’t require consumers to separate recyclable materials from non-recyclable waste, but requires additional screening at the recovery facility.

Aggregates Equipment, Inc. (AEI) is a leader in equipment manufacturing for the waste screening and recovery industry. Since 1950, we continue to provide custom engineered screening solutions to improve the solid waste screening process.

Global MSW Production Trends

According to the U.S. Environmental Protection Agency (EPA), the United States generated 292.4 million U.S. short tons in 2018. On a global scale, The World Bank estimates 2 billion metric tonnes of waste were generated in 2016.

The World Bank estimates that waste generation will increase to 3.40 billion tonnes by 2050. As more waste is generated around the globe, efficient screening becomes both a necessity and a challenge.

The U.S. solid waste management industry is estimated to have generated $63.4 billion in revenue in 2017; however, IBISWorld estimates only $7 billion was generated by recycling facilities in 2019. Efficient, modern screening solutions are needed to improve the solid waste screening and recycling processes, thus lowering costs and improving profits.

The Solid Waste Screening Process

Municipal waste management can be divided into four categories:

- Source reduction & reuse

- Recycling

- Energy Recovery

- Treatment & disposal

Screening is critical for the material recovery and recycling aspect of waste management.

For a recovery facility to properly manage incoming waste, it must be screened. After arriving at the recovery facility, materials are sorted via multiple separation methods.

Screening equipment sizes materials, allowing larger items, like cardboard and large plastic containers, to pass over the screen surface. Meanwhile, fines fall through the screen, where they are sorted separately. Examples of fines screened at the MRF include:

- Metal scraps

- Glass pieces

- Small plastic waste

Efficient screening of recoverable waste is vital for the environment and for a profitable management operation.

The Challenges Of Screening MSW

Municipal solid waste screening poses a number of challenges for recovery facilities. In some cases, these challenges can make recovery unprofitable.

High Operating Costs

Operating a recovery facility can involve high costs for labor, transportation, equipment, and maintenance. Inefficient equipment, which causes downtime or requires significant maintenance, can drive high costs. Contamination is one cause of screening equipment downtime that poses a significant risk to MRFs.

Contamination

Reducing recycling contamination has become increasingly important for MRFs. Strict international regulations have driven the need for a cleaner product. For example, China’s “National Sword” policy created tighter regulations on contaminant levels for many recovered materials. As a major importer of recovered materials, China’s regulations have pushed MRFs to produce a cleaner, less contaminated end product. Screening equipment like trommels or standard vibrating screens are often unable to reduce contamination to a sufficient level.

Material Quality

Careful screening is required to meet specifications for certain materials. Similar to contamination reduction, effective sorting ensures materials are separated by their unique properties. For example, some types of plastics are better suited for recycling. If the higher-quality plastics are mixed with lower-quality plastics, then the entire quantity of plastics will see a reduction in value. Modern sorting equipment must meet these demands.

AEI’s MSW Screening Solutions

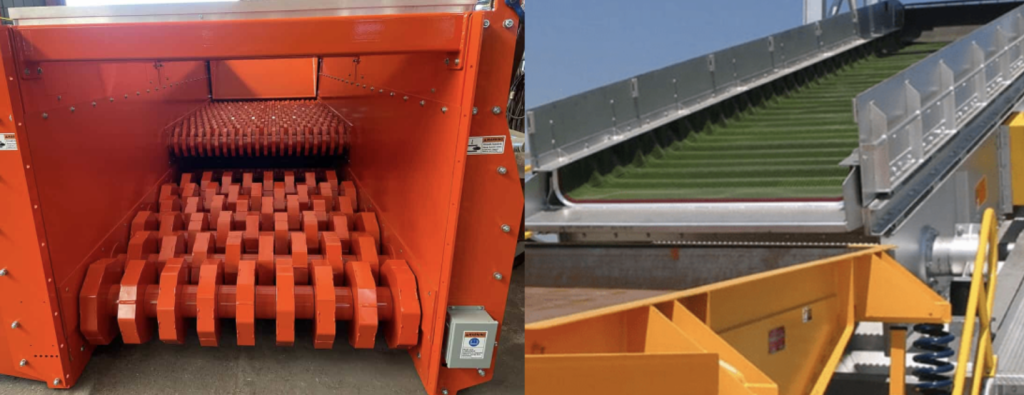

The Freedom Disc Screen

AEI’s Freedom Disc Screen is a high capacity, efficient screening solution designed to accurately size difficult to screen materials. Featuring robust HARDOX discs, the Freedom Disc Screen sizes solid waste without clogging, wrapping, or blinding the screen. As a result, its unique design reduces downtime and maintenance for MRFs, allowing higher sorting efficiency and less impact on your bottom line.

capacity, efficient screening solution designed to accurately size difficult to screen materials. Featuring robust HARDOX discs, the Freedom Disc Screen sizes solid waste without clogging, wrapping, or blinding the screen. As a result, its unique design reduces downtime and maintenance for MRFs, allowing higher sorting efficiency and less impact on your bottom line.

The BIVITEC

The BIVITEC flip flow screen uses a unique dual-vibratory principle to transfer high-acceleration forces to the screening surface. Coupled with its durable polyurethane screen panels, the BIVITEC is an ideal solution for efficiently separating plastic and metal fines from sticky or wet materials.

Request a quote online for more information or call 717-656-2131 to speak with our sales team and learn more about AEI’s screening solutions.