Vibratory screens are one of the main types of industrial screening equipment. There are several mechanical screening solutions available across the solid waste management, recycling, and aggregate industries. However, vibrating screens offer a number of unique advantages that make them a first-line option for a large variety of industrial applications.

What Is A Vibrating Screen?

As the name implies, vibrating screen design is based on the principle of transferring vibrations to a screening surface in order to separate and classify various particles by size. The different types of vibrating screens include:

- Linear: Using a linear motion, this screen conveys the material forward. It’s commonly used for fine and medium-sized materials, especially in industries like mining, metallurgy, coal, and construction.

- Inclined: Designed at an angle (typically between 15 to 30 degrees) to facilitate the movement of material, the inclined screen is suitable for wet or dry screening and is used in industries like sand and gravel processing.

- Circular: Its circular motion is suitable for classifying small to large particles. Providing consistent screening performance across the entire screen surface, it’s often used in the mining, quarrying, and aggregates industries.

- High-Frequency: Operating at a higher frequency allows for finer particle separation. A high-frequency vibrating screen machine is used in mineral processing, dewatering, and other applications requiring fine screening.

- Elliptical: The elliptical motion provides better screening efficiency for sticky or challenging materials. It’s commonly used in the mining and recycling industries.

- Banana: It has a distinctive banana-like shape and is used for high-capacity screening of materials with a high percentage of fines. This screen is commonly used in the coal and mineral processing industries.

- Dewatering: It’s designed to remove moisture from materials, making it suitable for processes like wet sand production and tailings management in mining.

- Grizzly: Consisting of bars or grids that remove oversized materials before they reach the primary crusher, it’s often used in the mining and recycling industries to improve crushing efficiency.

Regardless of the machine’s design, the principle remains the same: vibrations break down the surface tension between particles, in turn forcing them to separate. Undersized particles, known as “fines,” then fall through the screening surface. Meanwhile, oversized particles are carried over the screen surface. This is an important application in a large number of industries, particularly mineral processing.

Benefits of Vibratory Screens

Because of their unique design features, vibrating screeners offer specific benefits over other material processing equipment, including:

- Improved processing and material quality

- Lower operational costs

- Less maintenance and downtime

- Higher screening efficiency

- Improved sustainability

We’ll further detail these benefits below.

Improved Processing and Material Quality

While certain screening equipment is better suited for different materials, vibratory screens offer a number of advantages in aggregate and mining materials processing. Vibrating screens are particularly well-equipped to meet the fineness requirements of these industries. Their design, which is able to generate the force required to separate oversized particles from fines, results in easier recovery of product – even when handling a material that requires significantly smaller size separation. This leads to both higher yields and an overall improved quality of the final product.

Lower Operational Costs

Vibrating screeners are known for their robust design. Because the operating principle is relatively simple, and the design of modern machines is streamlined, the screens can generally be purchased for less than other types of screeners. This results in a lower upfront investment.

Additionally, these screens are able to operate with lower energy consumption than more complex machinery, in turn saving businesses money in ongoing operational costs. Lastly, because higher frequency vibrations are transferred directly to the screening surface, only the screen media needs to be regularly replaced. This can help to save on maintenance and repair costs often posed by other screening equipment choices.

Less Maintenance and Downtime

Maintenance and downtime as a result of repairs or equipment failures can lead to a major loss in both productivity and profit. Many types of screens undergo significant wear and tear, particularly in demanding applications like aggregate processing. However, vibratory screeners offer the advantage of less maintenance and downtime. This is a result of their design, which centers around delivering vibratory forces only to the screening surface.

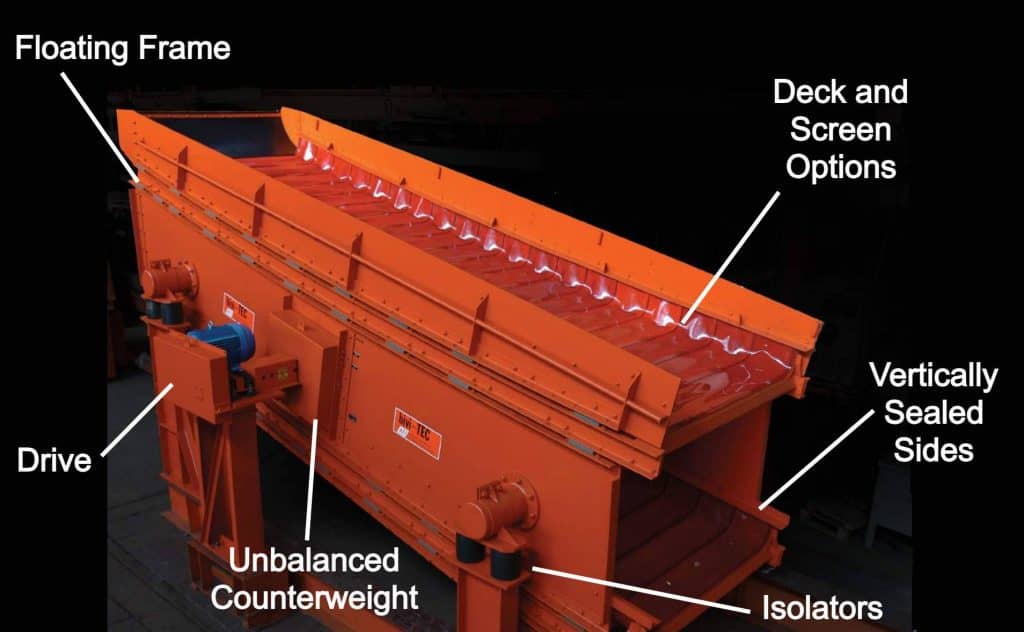

In addition, quality vibrating screening equipment is designed and manufactured so that other parts of the machine are minimally affected by vibration forces. In more sophisticated designs, the machine is constructed to allow for adequate absorption and dampening of vibrations outside of the screen media. This results in fewer moving parts and overall less wear and tear to the machine, further reducing both downtime and maintenance.

Higher Screening Efficiency

While there is a wide range of screening equipment available on the market, vibrating screen machines offer an ideal choice when an operation requires a simple solution that can handle a higher feed flow. In fact, they work most efficiently with a consistently higher flow rate. For other types of screening equipment, the same material throughput could lead to screen blinding or a backflow of materials that requires a slower feed.

Improved Sustainability

Incorporating vibrating screens into industrial processes can result in a range of environmental benefits, from reduced energy consumption and emissions to improved resource efficiency and waste reduction. By accurately separating materials based on size and quality, many different industries can make the most of their resources.

AEI’s BIVITEC® Vibrating Screen Solution

Developed with the most demanding applications and challenging materials in mind, AEI is proud to offer the BIVITEC® vibratory screen. The BIVITEC® design features a unique dual-vibratory, flip flow screening process that helps ensure operations remain productive by eliminating clogging and blinding of the screen openings to reduce maintenance, downtime, and drive efficiency. Learn more about the BIVITEC® or contact us to request a quote.