Single-use plastic bags are a common sight in many countries, particularly the U.S. While reusable tote bags have become a popular alternative, plastic bags are still widely used.

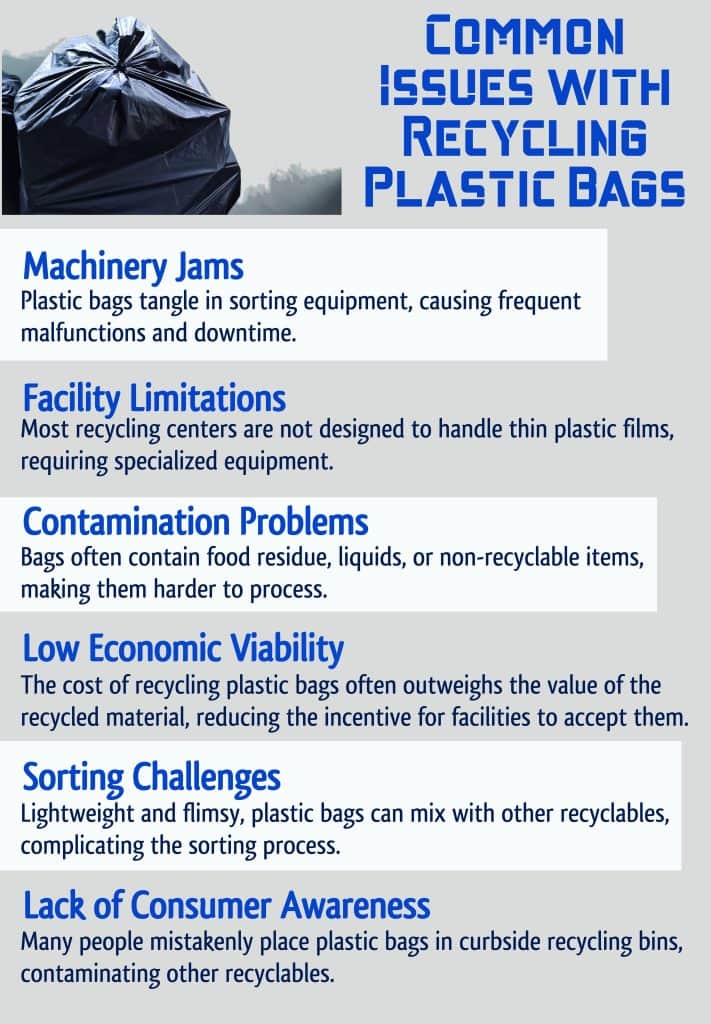

Outside of their environmental impact, plastic bag contamination reduces the efficiency of the recycling process when they’re improperly recycled.

What Is Plastic Bag Contamination?

Recycling “contamination” occurs when plastic bags or other non-recyclable materials enter the recycled waste stream. To fully understand contamination, it’s necessary to understand the recycling process itself.

The Recycling Process

There are two types of consumer, or “curbside,” recycling: single stream and dual stream.

Dual stream recycling requires consumers to pre-sort recycles before placing them at the curb for pick-up by a hauler. Typically, this involves separating recyclable paper products from plastics.

Single stream recycling does not require consumers to sort their recycling. Instead, all recyclable items can be placed in the same bin for haulers to collect.

Both types of recycling have their share of benefits and drawbacks. Single stream has risen in popularity as it increases consumer participation in municipal recycling programs. However, the increased participation results in higher contamination rates.

Single Stream Contamination

When more people recycle their waste as a result of a single stream collection program, more items end up in the recycling bin – including items that shouldn’t be there. This is partly a phenomenon known as “wishcycling.”

Sometimes people recycle items, made from plastic and other materials, they believe are recyclable but actually aren’t. This is wishcycling. This behavior is most common with single stream recycling programs. Because all recyclables can be placed in the same bin, it’s easy for consumers to assume a larger range of items can also be recycled.

Wishcycling is the main reason that plastic bags end up in the recycled waste stream. Unfortunately, the well-meaning intentions of consumers lead to significant problems later in the recycling process when plastic bags arrive at recovery facilities.

Plastic Bags Make Waste Screening Difficult

After plastic bags are tossed into the recycling bin, their final destination is a Material Recovery Facility, or “MRF.” At these facilities, recyclables are sorted and then sold to material processors who turn them into usable materials. A key part of the sorting process is screening. It’s during screening that plastic bags become a problem.

Most MRFs use a variety of screening equipment to help sort and size recyclables. One of the most common types of screening equipment is a star screener. As the recycled material travels across the screening equipment, star-shaped discs separate materials.

Larger materials, like cardboard, pass over the discs, while small items, like glass and plastic bottles, fall between gaps in the screen surface. However, when plastic bags travel across the screening surface, they become wrapped in the star discs.

Looking for screening equipment that won’t clog?

Screen Wrapping And Blinding

As plastic bags wrap around the star screener, they cause a number of problems:

- Plastic bags can damage the screening equipment as they tangle around the discs.

- Once tangled, plastic bags cause screen blinding. This prevents smaller materials from passing through the screen.

- To prevent further damage and ensure the screen is working at peak efficiency, the machine must be stopped and the bags manually removed from the screen.

Together, these problems cause compounding issues. When blinded, the screen works at a lower efficiency. As a result, materials that should be sorted into a separate stream remain mixed with the wrong material. For example, glass shards mix with paper waste. This requires an extra stage of sorting to remove the glass or the paper waste may not be accepted by the processor.

Further, if the screening equipment has to be shut down for maintenance or repair, recycled waste can’t be processed. This waste builds up, increasing the likelihood of further contamination.

Reducing Plastic Bag Contamination

Reducing plastic bag contamination is a challenge. Many municipalities and cities have begun banning the use of plastic bags. Some stores have also joined this initiative and have stopped offering plastic bags or switched to a non-plastic material. However, true reduction has to begin at the consumer level.

Consumer Education

Whether you’re an MRF, a municipality, or an environmental organization, the first step is community outreach and consumer education. In other words, contamination must be prevented at the source. Many people do not know which materials can be recycled or how to recycle them – this is especially true concerning plastic materials like bags.

Often, outreach to schools is one way to begin recycling education initiatives early. MRFs, recyclers, municipal organizations, and other entities often have outreach programs that can partner with local schools, providing first-hand education and additional resources for teachers to share with their students.

Other avenues to provide education include social media, websites, and email newsletters. Simple infographics can go a long way in making larger amounts of information easily digestible and shareable.

Investing In Advanced Technology

On the processing side, recyclers and MRFs can invest in newer technologies that more efficiently screen waste. While no system is perfect, older screening and processing equipment is more susceptible to damage and inefficiency resulting from plastic bag contamination.

Furthermore, national and international regulations, standards, and policies change. Older sorting and screening equipment may have been engineered to meet different contamination standards. Meeting today’s regulations necessitates modern screening solutions.

AEI’s Solutions For Waste Screening

At Aggregates Equipment, Inc., we understand the challenges faced in waste processing and materials recovery. We’ve designed screening solutions to meet those challenges.

AEI’s Freedom Disc Screen is engineered around an innovative anti-clogging system. By utilizing high-durability HARDOX disc screens, urban and industrial waste is safely and efficiently screened. As a result, production slowdowns caused by problematic materials that clog, wrap and blind the screen, like plastic bags, are mitigated.

Learn more about the Freedom Disc Screen’s capabilities or connect with our sales team for an equipment quote.